Description

Functioning

The filling system, which is based on the regulation of the vibrations speed and intensity (variable depending on the container dimensions), allows to vary the quantity of the product to be filled.

Containers move forward on a conveyor with trapezoidal belt which positions them in the filling zone.

The product fed from the gooseneck bucket elevator is gently discharged on the distribution device and then it is gently transferred on the filling hopper without any damage.

At this stage the product coming from the filling hopper is filled inside the containers without stopping.

During the filling phase the containers are subjected to vibration by means of mechanical devices, both laterally and from the bottom, to allow the product to settle inside the containers.

Subsequently, the containers reach the pouring out area where, by means of vibrating inclined guides, the exceeding product pours out.

The containers are then straightened and subjected to jets of air generated by an electro blower to remove any residues of product from their external surface.

Manufacturing Features

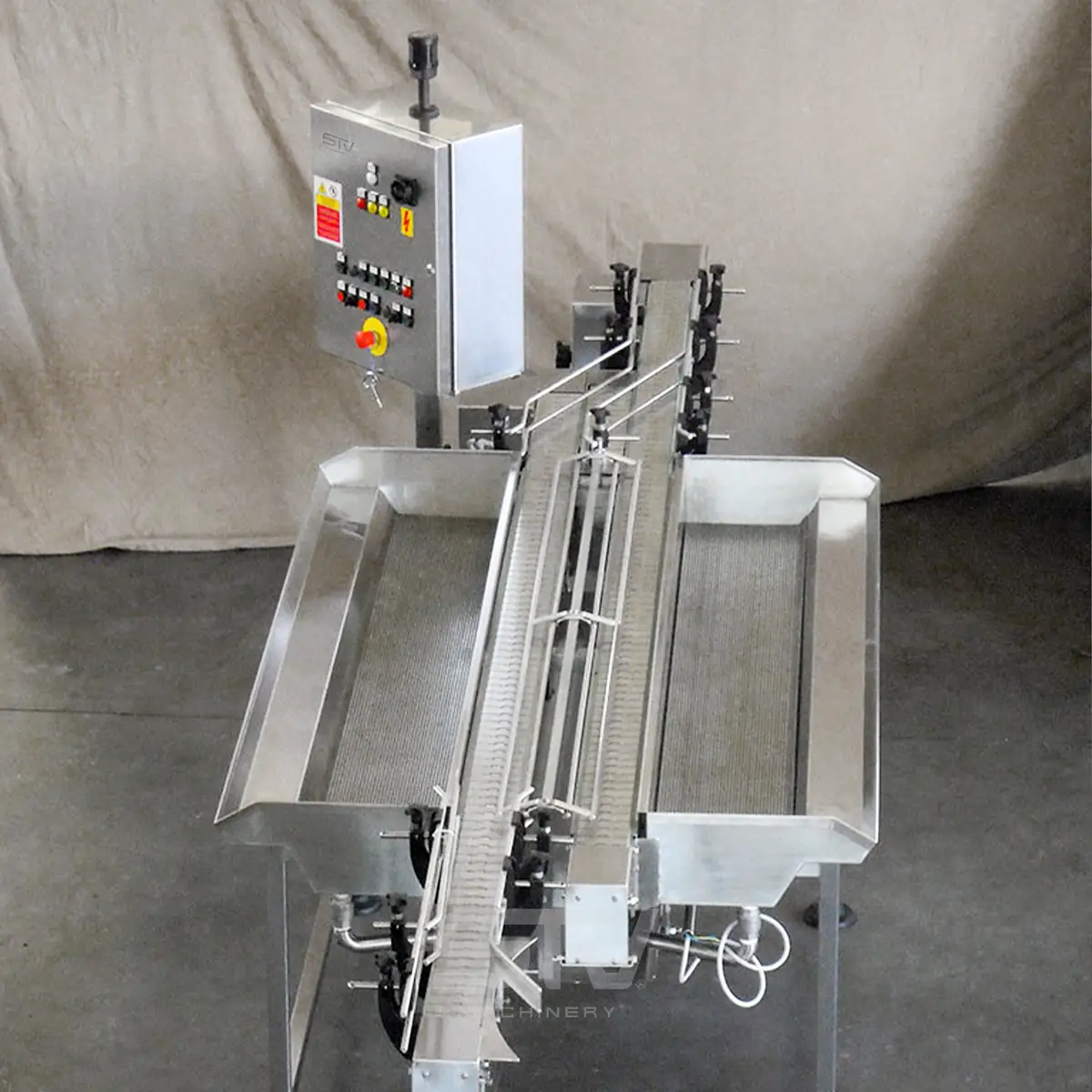

- AISI 304 stainless steel structure.

- Gooseneck bucket elevator in polypropylene.

- Product collecting tank for elevator feeding.

- Vibrating hopper for product filling.

- Conveyor belt for containers transmission.

- Conveyor for exceeding product recovery.

- Driving by adjustable speed motor.

- Electric control board in stainless steel.

Available Models

The machine is available in two models:

- Mod. RPN 750 – max. output capacity: 6.000 containers / hour approx. of 314 ml.

- Mod. RPN 1500 – max. output capacity: 14.000 containers / hour approx. of 314 ml.