Description

Functioning

Containers filled by means of the Motor-driven Filling Table or the Vibration Filler enter the Vacuum Filler on a conveyor, then they are positioned under the vacuum filling valves by a group with screw in polyzene and supports adjustable according to the size of the container.

At this stage, by the pneumatic cylinder, the valves lower and position themselves on the container, thus starting the filling procedure according to the phases:

- Vacuum formation.

- Filling with the liquid.

- Vacuum breaking by contact with environment air.

After the container has been vacuum filled it is conveyed to the Capper.

Fast change of the equipment for containers of different diameter and height.

After the start-up and the relevant adjustments the machine does not need any operator assistance.

Manufacturing Features

- Basement with height adjustable feet, supporting plate in carbon steel, structure and total covering with inspection doors in stainless steel. The basement includes a liquid ring vacuum pump and the air treatment group with solenoid valves.

- Vacuum tank connected to the pump, equipped with vacuum gauge, manhole for washing operations and discharge valve.

- Filling-liquid tank with float for level control.

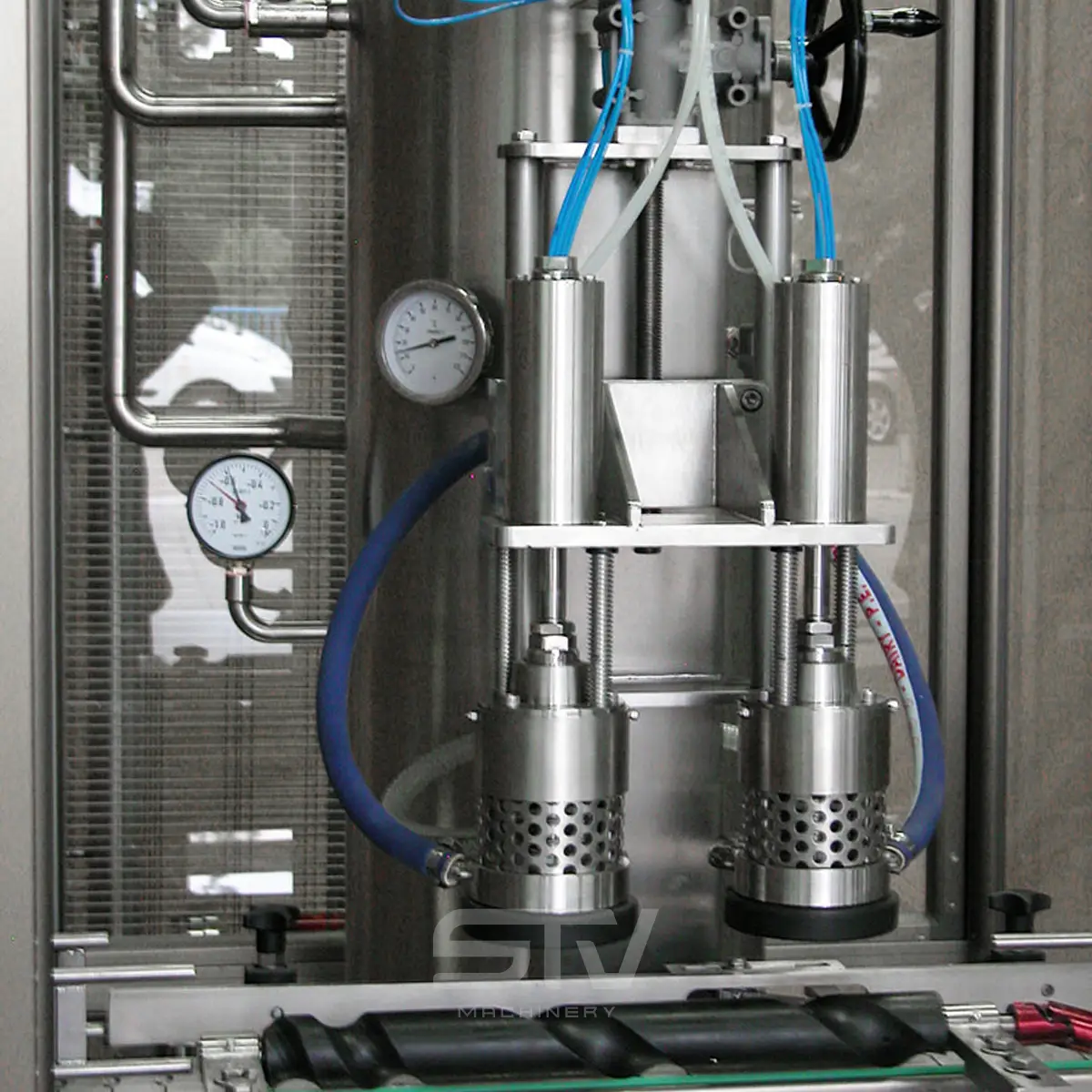

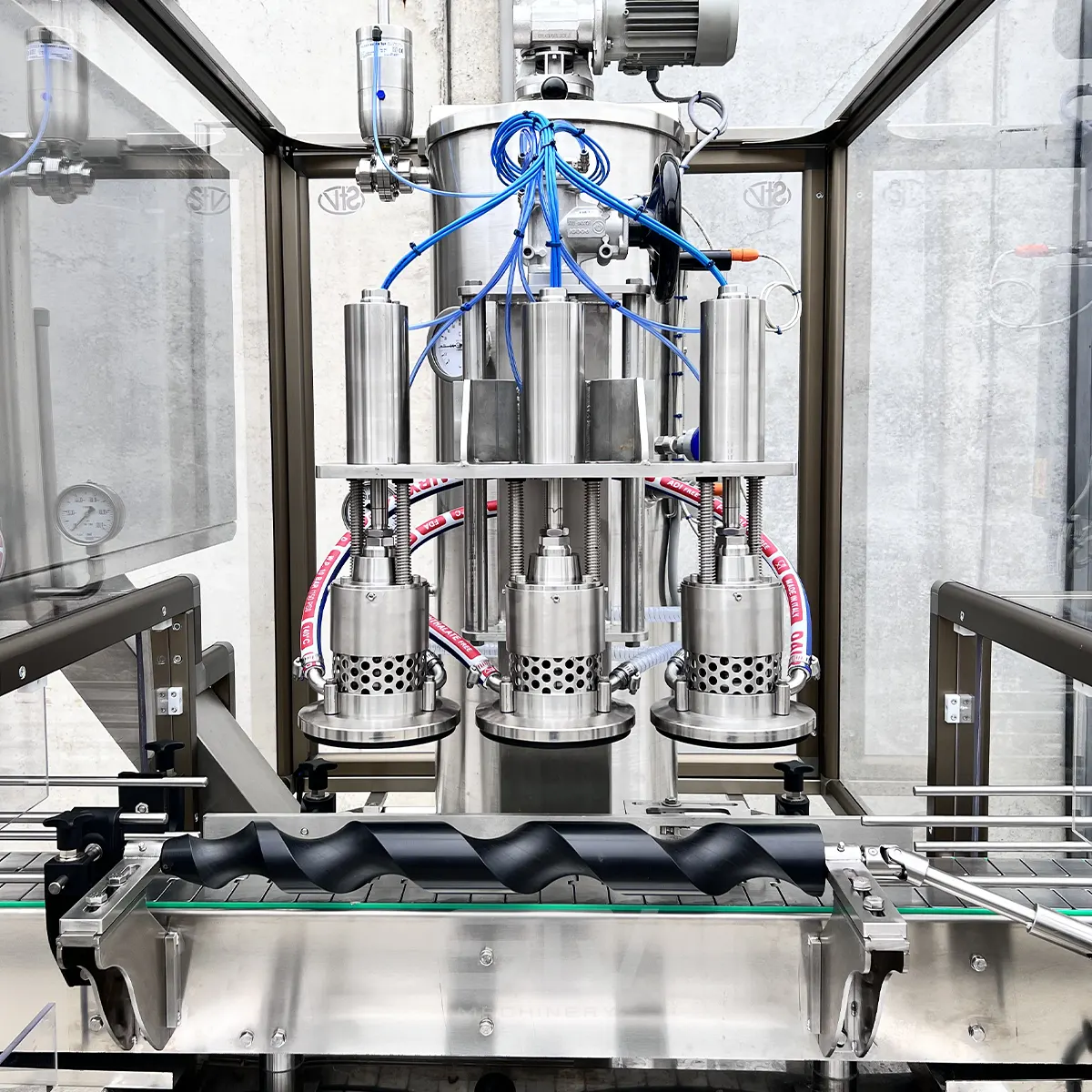

- No. 2 special vacuum filling valves (STV patented), without sliding seals, connected by flexible pipes to the vacuum tank and to the filling-liquid tank.

- Valves unit equipped with pneumatic cylinders for the lifting and lowering motion, mounted on a supporting column with mechanical device (wheel) for height adjustment.

- Stainless steel conveyor with table-top chain conveyor mounted on anti-friction material strips and fitted adjustable containment guides.

- Centralised single driving unit for all mechanical parts.

- Pre-arrangement for machine feeding by pump or gravity.

- One screw for one size of container is supplied with the machine.

- Electric control board in stainless steel.

- Manufacturing in AISI 304 stainless steel, except for some parts which are in a different material suitable for their functioning.

- Safety protection system as per CE norms.

Technical Data

| Output capacity | 1000 containers/h approx. of 314 ml |

| Installed Power | kW 3,60 approx. |

| Length | 3.000 mm |

| Width | 1.100 mm |