Description

Functioning

Our Monoblock is a MODULAR system according to the required functions:

- FILLING of dense and semi-dense products either sweet (jam, honey, yogurt, etc.) and salted (mayonnaise, sauces, paté, etc.) containing also small solid pieces.

- VACUUM FILLING with liquids (oil, vinegar, brine, syrup) of containers PREVIOUSLY filled with solid products (vegetables in oil/brine, legumes, fruits in syrup, etc.) by means of the Motorised Filling Table or the Vibration Filler mod.RPN.

- CLOSING of glass jars/bottles by twist-off caps or PET containers by plastic screw or press-on caps.

In all versions the PRE-SETTING for the future INSTALLATION OF A METAL DETECTOR UNIT is available.

Main Advantages

- Low consumption

- High reliability

- Reduced dimensions

- Quick format changeover

- Maximum flexibility

- Simple cleaning

- Respect of product integrity

Type of Containers

| Type of Containers | GLASS JARS/BOTTLES | TIN CANS | PET CONTAINERS |

|---|---|---|---|

| FILLING | X | X | X |

| VACUUM FILLING | X | X | X |

| CLOSING | X | X |

Productivity

| MOD. | DESCRIPTION | OUTPUT CAPACITY / HOUR [*] (100 ml Containers) |

|---|---|---|

| DC | 1 filling valve for dense / semi-dense products + closing unit | 1.600 |

| 2DC | 2 filling valves for dense / semi-dense products + closing unit | 3.000 |

| CC | 1 vacuum filling valve for liquids + closing unit | 500 |

| 2CC | 2 vacuum filling valves for liquids + closing unit | 900 |

| DCC | 1 filling valve for dense / semi-dense products + 1 vacuum filling valve for liquids + closing unit | 1.600 (dosing and closing) 500 (vacuum filling) |

| 2D2CC | 2 filling valves for dense / semi-dense products + 2 vacuum filling valves for liquids + closing unit | 3.000 (dosing and closing) 900 (vacuum filling) |

| 2DCC | 2 filling valves for dense / semi-dense products + 2 vacuum filling valves for liquids + closing unit | 3.000 (dosing and closing) 500 (vacuum filling) |

| D2CC | 1 filling valve for dense / semi-dense products + 2 vacuum filling valve for liquids + closing unit | 1.600 (dosing and closing) 900 (vacuum filling) |

[*] to be considered as indicative, since it varies depending on the type of product and the container’s dimensions.

Manufacturing Features

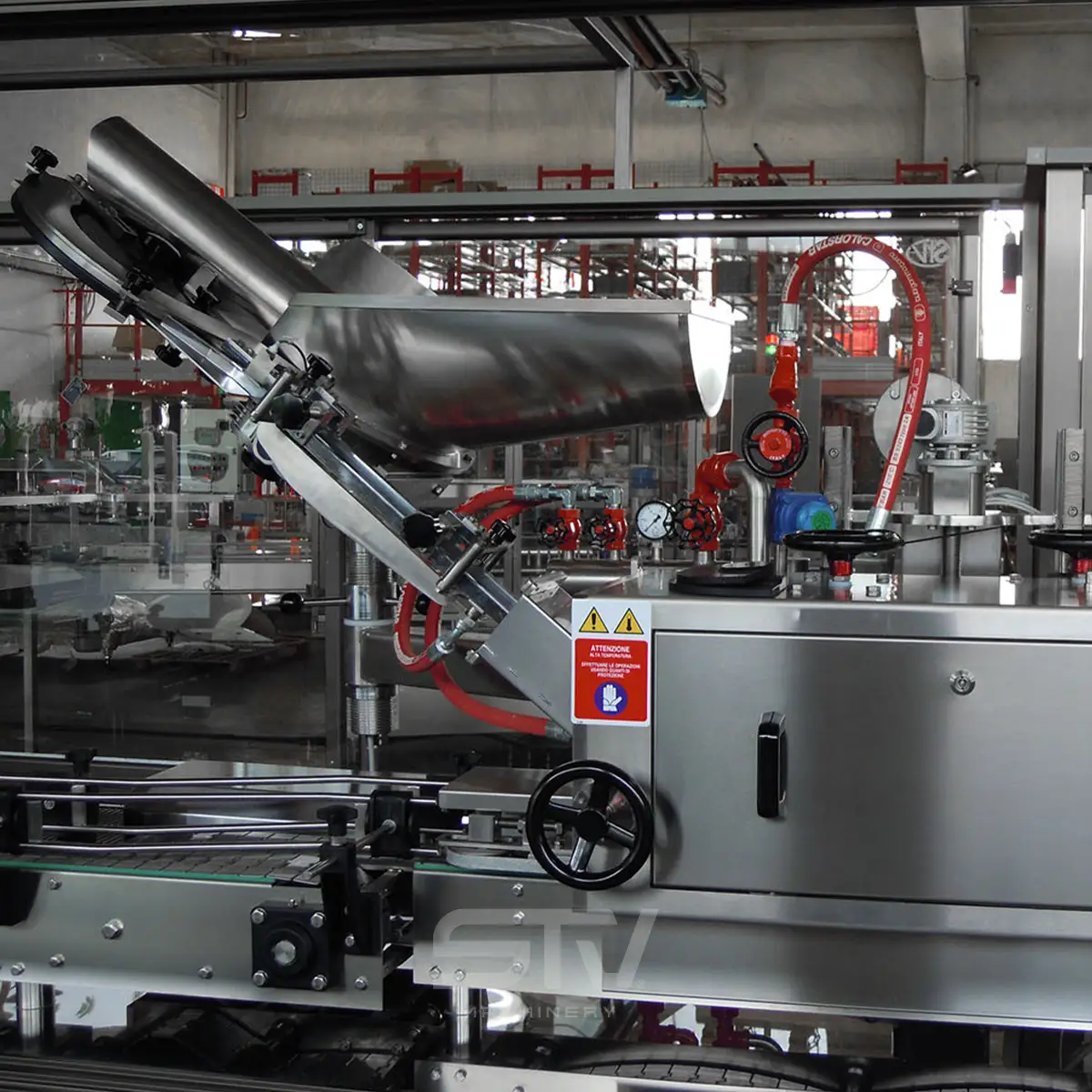

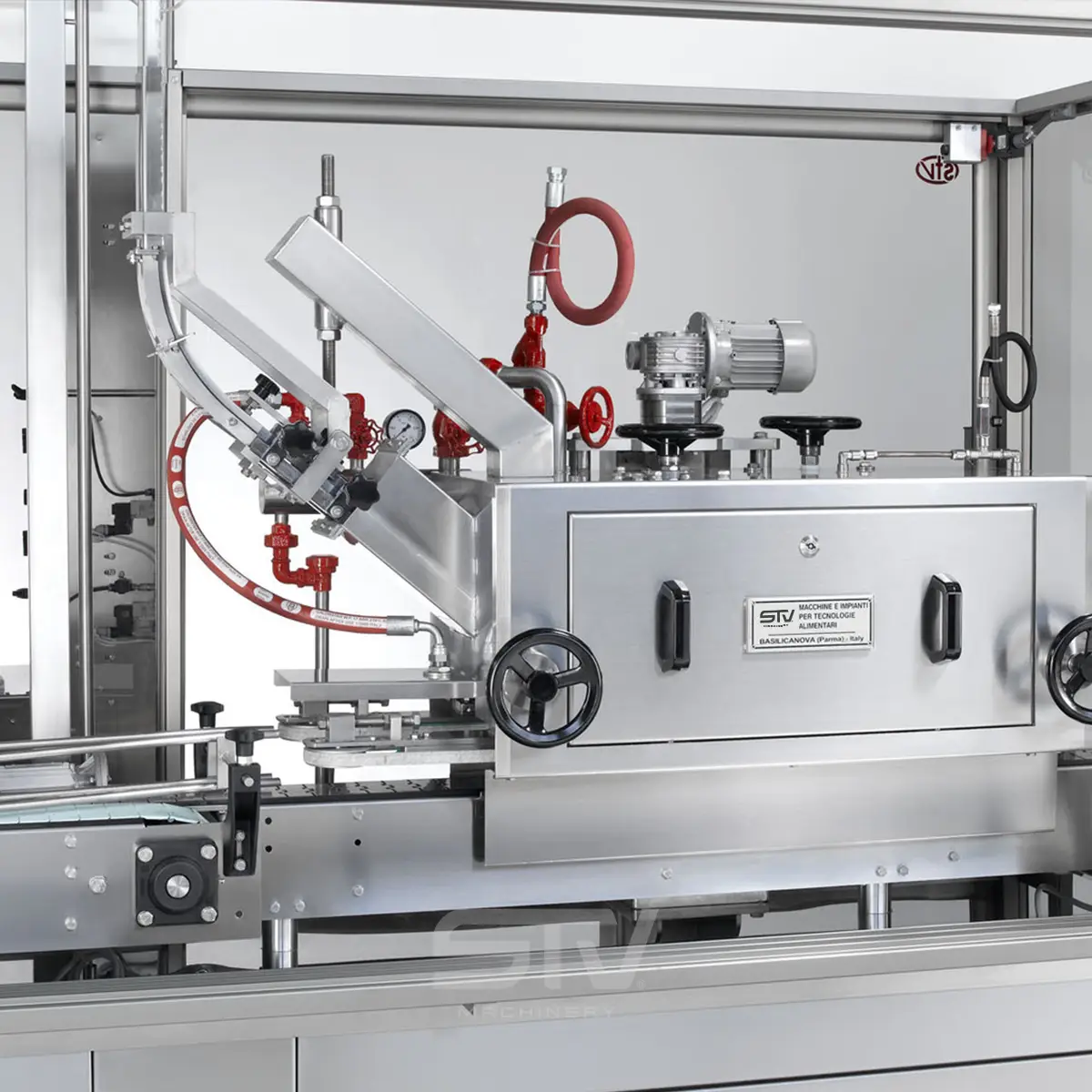

- Basement with height adjustable feet, supporting plate in carbon steel, structure and total covering with inspection doors in stainless steel.

- The basement includes:

- In the version Filling + Capping: a jack with external hand wheel for the dosing unit height adjustment and the air treatment group with solenoid valves.

- In the version Vacuum Filling + Capping: a liquid ring vacuum pump for the vacuum filler and the air treatment group with solenoid valves.

- On the top of the basement the following equipment is installed: a conveyor with stainless steel table top chain mounted on strips in anti-friction material and adjustable containment guides for the containers feeding to the Monoblock and motion to its groups, a head controlled by gear motor and a idle head.

- Electric control board in stainless steel.

- Manufacturing in AISI 304 stainless steel, except for some parts which are in a different material suitable for their functioning.

- Safety protection system as per CE norms.

- After the start-up and first adjustments the machine does not need any operator assistance.

Technical Data

| Length (including inlet and outlet conveyors) | 6.000 mm MAX. (corresponding to the most complete version 2D2CC) |

| Width | 1.200 mm |