Description

Functioning

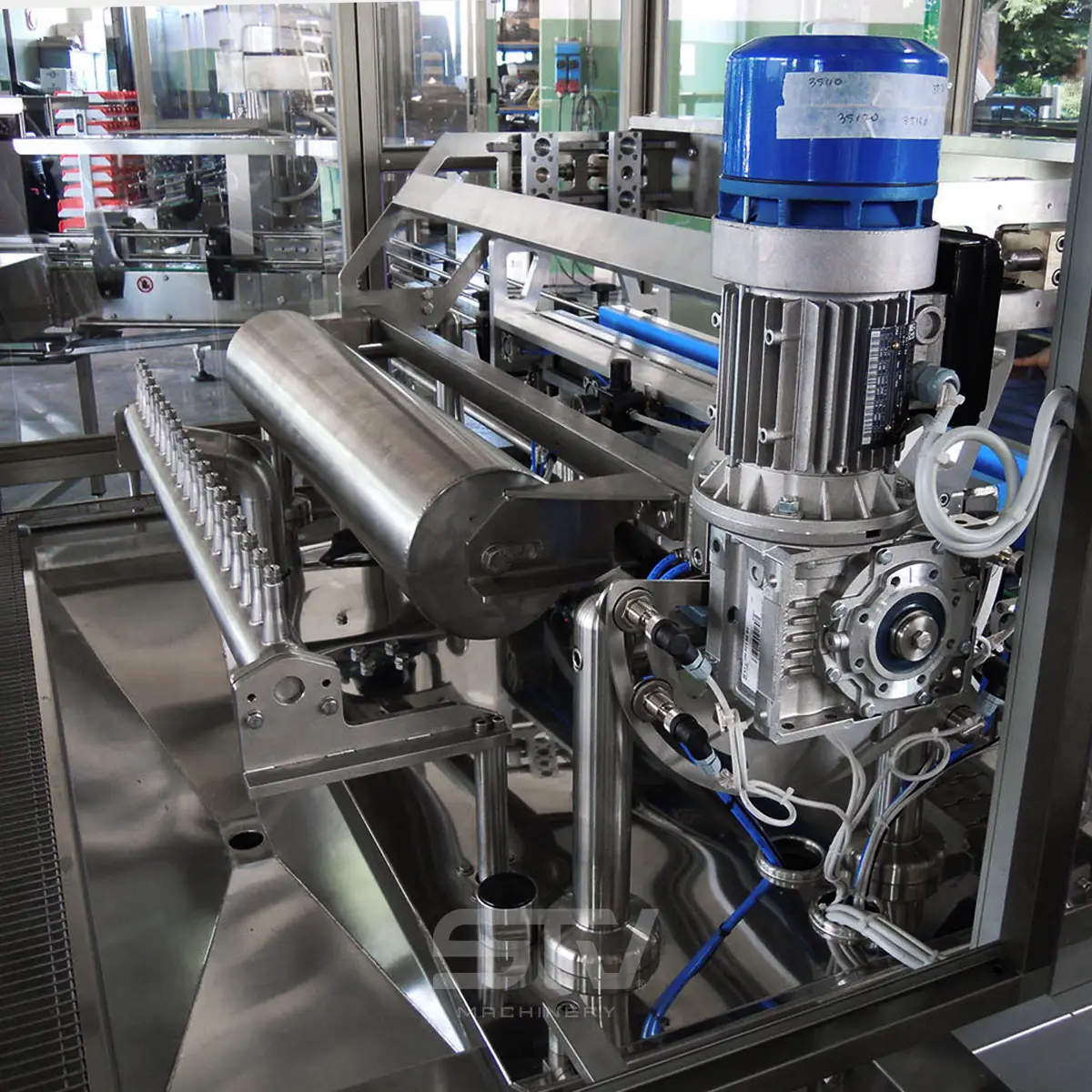

In the first section of the twist containers make a 180° rotation and present themselves upside-down on the intermediate section of the twist itself. Here a set of nozzles sprinkles air (produced by an electric fan) inside the containers. Then containers are injected with steam by a manifold equipped with control devices (if not requested the steam manifold is not installed). Afterwards, containers enter the third section of the twist where they make another 180° rotation before reaching the filling position.

Format changeover is performed by replacing the twist, which is fixed on two supports positioned inside the bodywork, and by intervening on the handwheels to adjust the pusher to new container diameter.

Manufacturing Features

- AISI 304 stainless steel frame with hinged cover and height-adjustable supporting feet.

- Pushing unit.

- Electric fan.

- Steam injection device (if requested).

- One twist for one size of container is supplied with the machine.

- Electric control board in stainless steel.

- Safety protection system as per CE norms.

Optionals

On demand, the machine can be supplied with FEEDING TABLE FOR EMPTY CONTAINERS in AISI 304 stainless steel (diam. 1.000 mm) with round plane in plastic material (polyethylene).

Technical Data

| Output Capacity | 6.000 containers/h of 314 ml |

| Installed Power | kW 2,60 |

| Length | 3.000 mm |

| Width | 500 mm |